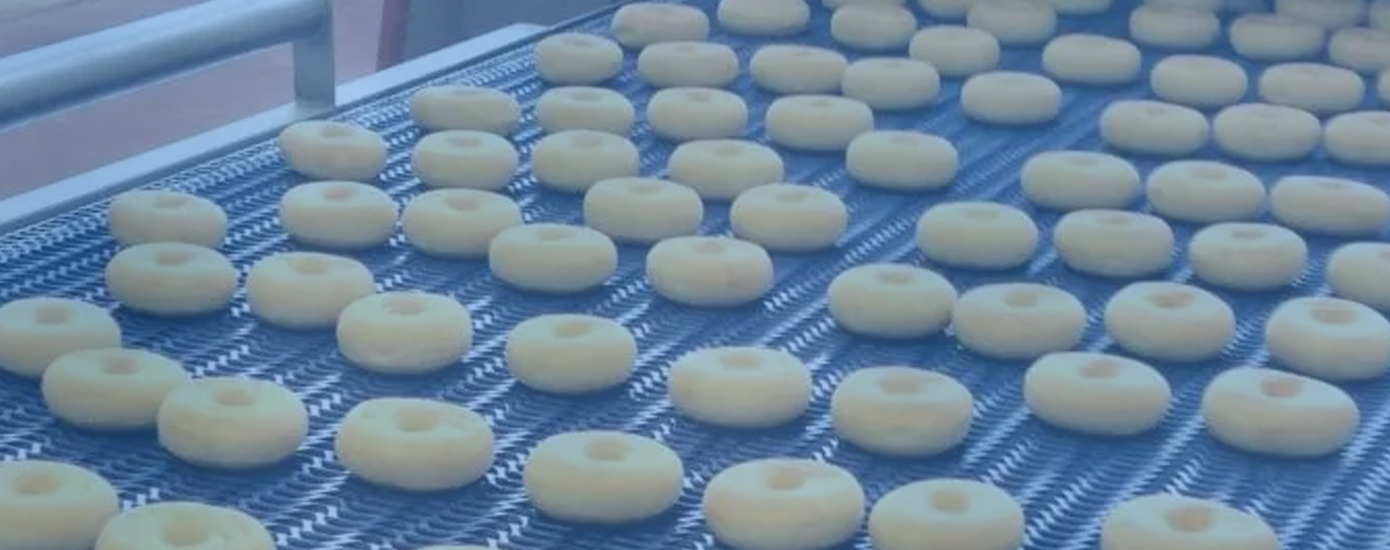

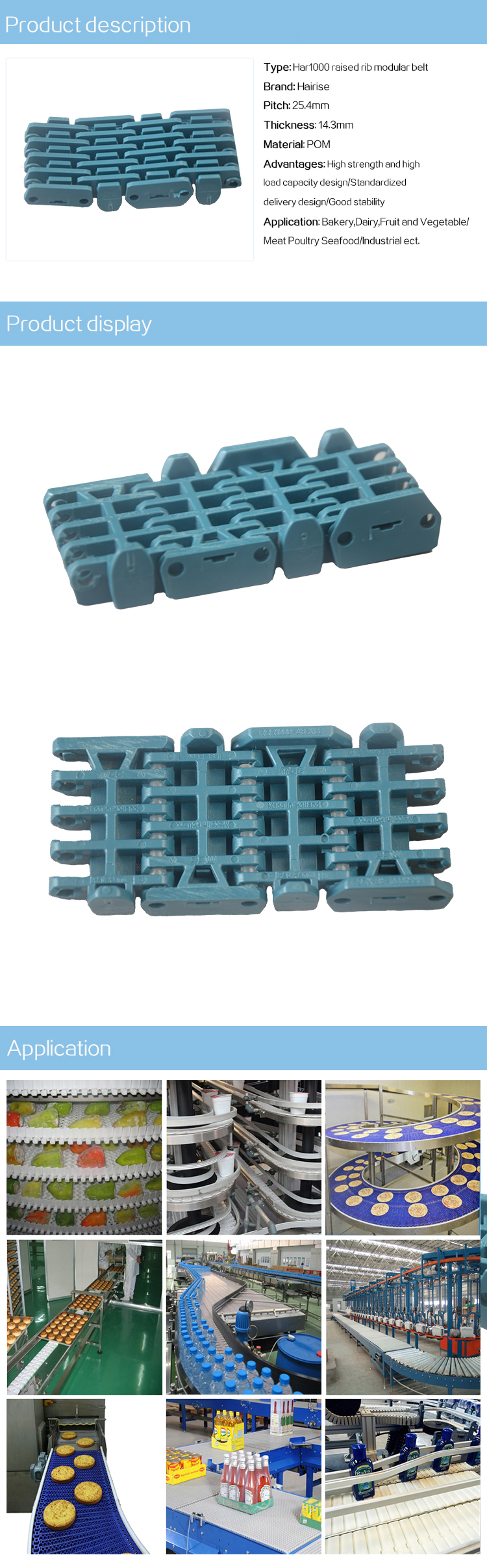

Har1000 series raised rib modular belt

Modular belt:

Complete range of modular belts and chains, offered in different pitches (from 8 mm pitch to 2") and top surface execution, to suit any application.Flat Top Belt has a smooth surface without holes (used to transport general products).Perforate Flat Top Belt has an overall appearance similar to the flat top but has a slot hole for ventilation and liquid.Flush Grid Belt is commonly used in production lines that require cleaning of materials and for cooling. There are openings> 20% of the belt area. Designed to drain water and air.

Raised Rib Belt. There are thin ridges along the longitudinal belt of some models. Wear a Finger Plate to connect between the belts. Which the thin ridge raised Is to reduce the friction of the material with the belt surface.Rubber Top Belt is the use of rubber (Rubber) to be attached to the belt. To help prevent slipping of the material while conveying in a vertical position.Roller Top Belt is used to convey and change the direction of the packing (Sorting) of the package.

The advantages of a plastic modular belt:

Selecting a belt for a conveyor is like deciding which tire is best for the road. Baked foods and snacks can travel on all types of surfaces ranging from a flat belt to modular plastic to a metal or wire one. Some are rugged, others are all-weather, and nearly every one of them guarantees a smooth ride.

Then again, does the style of conveyor determine the type of belt? Here are some of the advantages of plastic modular belts for your conveyors.

Plastic modular belts are perfectly suited to going round bends and curves

They can be easily repaired ( in the event of a breakage) and extended should the need occur. This has the advantage that the plastic belts can be changed quickly.

Easily cleaned they are easy to wash down with water

Versatility is the name of the game and plastic modular belts are suitable for incline and decline applications and linking to elevating conveyors. Variable speeds can be fitted to suit your products

can be easily fitted or retro fitted. Side guides can be fitted to your conveyor

A wide variety of food products can be transported

Raw food products can be transported on plastic belts ( a bi product of the easy cleaning capability)

Wet or dry products are ideal on modular belt conveyors

Hot or cold products can be transported

All of which are can be used for accumulation of products

Why use Hairise Plastic Belt Conveyors

Hairise have been designing and fabricating conveyor systems for over 16 years

Hairise have an enviable record of delivering conveyor systems on time and to budget

Where third party components are required i.e. motors / bearings only the best quality components are used.

Our engineers are available to conduct conveyor audits and provide on site technical advice

Hairise maintenance and repair service is available to food processing companies to minimise down time

Share this article on facebook or LinkedIn.