Why Are Guide Rails Important?

Why Are Guide Rails Important?

Product Alignment – Guide rails maintain the correct position of goods, especially in high-speed production lines.

Safety – Prevents products from slipping off the conveyor, reducing waste and accidents.

Flexibility – Adjustable guide rails for conveyor system allow manufacturers to handle different product sizes and shapes without changing the entire setup.

Efficiency – By reducing product jams or misalignment, they improve overall workflow and minimize downtime.

Common Applications of Guide Rails

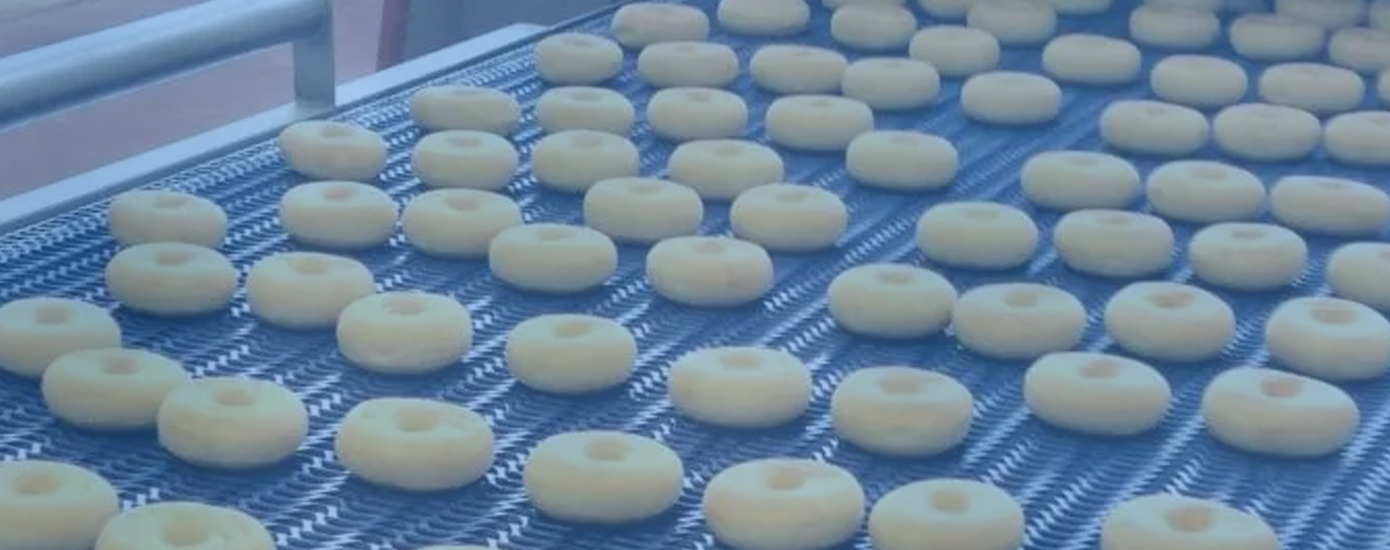

Food & Beverage Industry: Bottles, cans, and packaged goods are kept in line during filling and labeling.

Pharmaceuticals: Ensures small containers or medicine packs are precisely guided.

Logistics and Packaging: Boxes and parcels move smoothly without tipping over.

Automotive & Electronics: Delicate parts are kept stable during assembly.

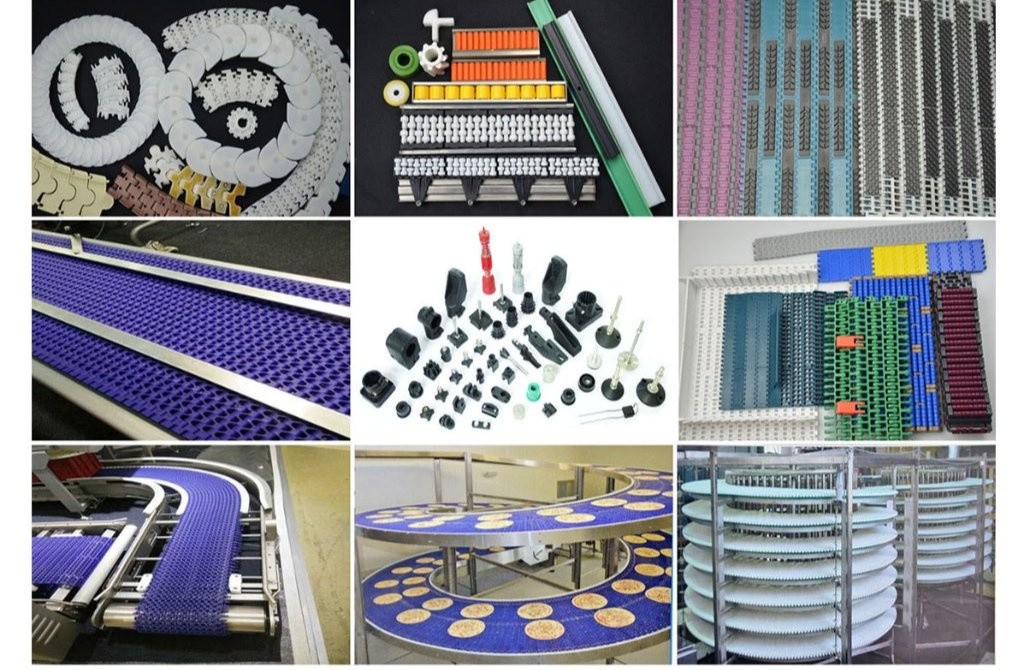

Types of Guide Rails

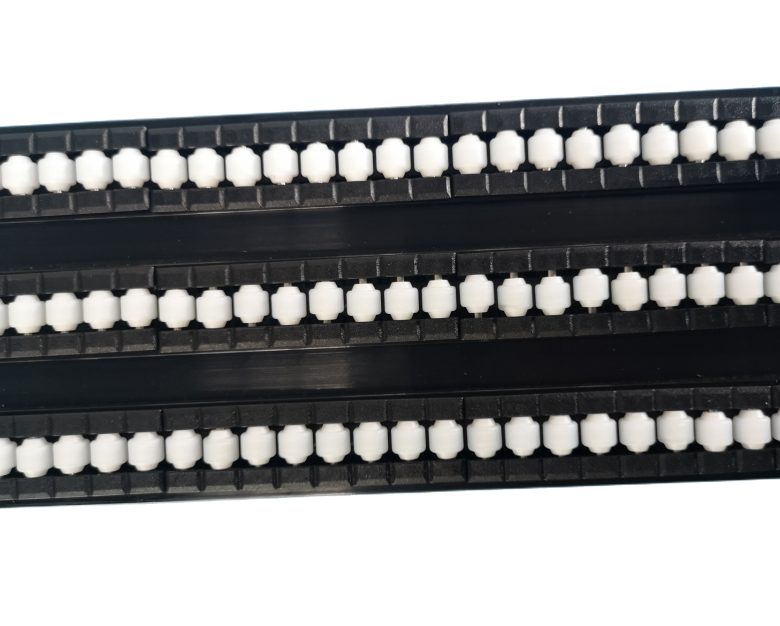

Fixed Guide Rails – Installed permanently, suitable for consistent product sizes.

Adjustable Guide Rails – Can be repositioned to fit different widths, offering more flexibility.

Custom Guide Rails – Designed for unique conveyor layouts and specialized industries.

Conclusion

Simply put, guide rails for conveyor system are essential accessories that ensure smooth, safe, and efficient material handling. They help businesses maintain product quality, increase productivity, and adapt to diverse manufacturing needs.