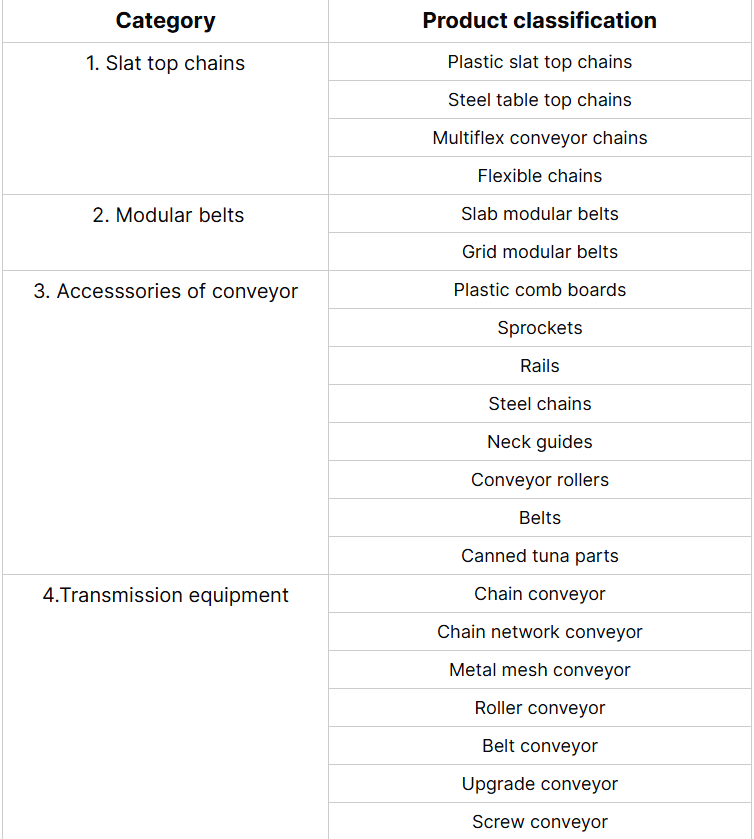

What Is a Sprocket in a Conveyor System?

A sprocket is a crucial mechanical component used in conveyor systems to transmit rotary motion and drive the conveyor chain or modular belt. It is a wheel with evenly spaced teeth that engage precisely with the conveyor chain links, allowing the chain to move smoothly and efficiently along the system. Without a sprocket, a conveyor system cannot function properly — it is the driving heart of the entire transmission mechanism.

Structure of a Conveyor Sprocket

A typical conveyor sprocket consists of:

Teeth: These are designed to fit perfectly into the gaps of the chain or modular belt, ensuring accurate movement without slipping.

Hub or Bore: The central part that mounts onto the conveyor shaft.

Material: Conveyor sprockets are usually made of stainless steel, engineering plastic (POM, PP), or carbon steel, depending on the working environment.

Plastic sprockets are commonly used in food, beverage, and packaging industries due to their corrosion resistance, while metal sprockets are preferred for heavy-duty or high-temperature applications.

Function of a Sprocket in Conveyor Systems

The primary function of a sprocket in a conveyor system is to transfer power from the motor to the conveyor chain or belt. When the sprocket rotates, its teeth engage with the chain, pulling it forward and moving the products along the conveying line.

In addition, sprockets help:

Maintain precise chain alignment

Reduce chain wear and slippage

Support synchronized movement in multi-drive systems

Ensure smooth and stable conveying

Types of Conveyor Sprockets

Single row sprocket – Used for standard chain conveyors.

Double row sprocket – For higher load capacity and dual-chain systems.

Split sprocket – Easy to install or replace without removing the shaft.

Idler sprocket – Used for guiding or tensioning the chain.

Each type of sprocket is designed to meet specific industrial needs, ensuring reliable performance under different working conditions.

Applications of Conveyor Sprockets

Conveyor sprockets are widely used in:

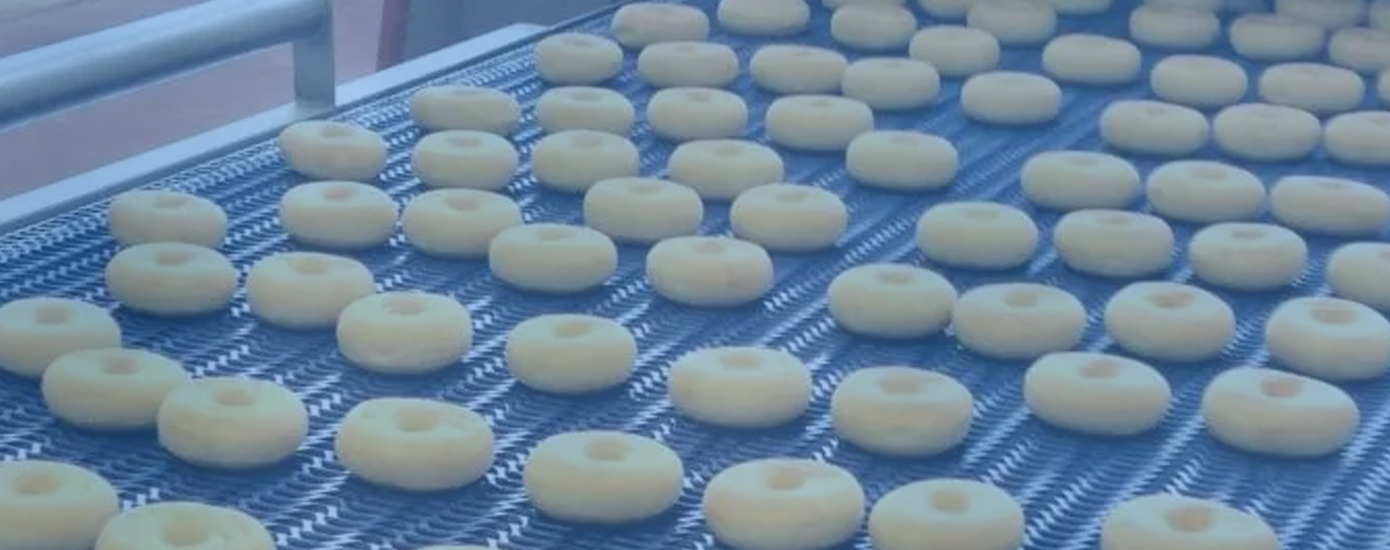

Food and beverage industry: For bottle filling, packaging, and labeling lines.

Logistics and warehousing: In sorting and distribution conveyors.

Automotive and manufacturing: For assembly and parts transfer lines.

Pharmaceutical and cosmetic industries: Where hygiene and precision are required.

Advantages of Using High-Quality Conveyor Sprockets

✅ Durability: Long service life even under continuous operation.

✅ Low maintenance: Easy installation and replacement.

✅ Smooth operation: Reduced vibration and noise.

✅ Energy efficiency: Improved transmission performance.

✅ Compatibility: Works perfectly with modular belts and tabletop chains.

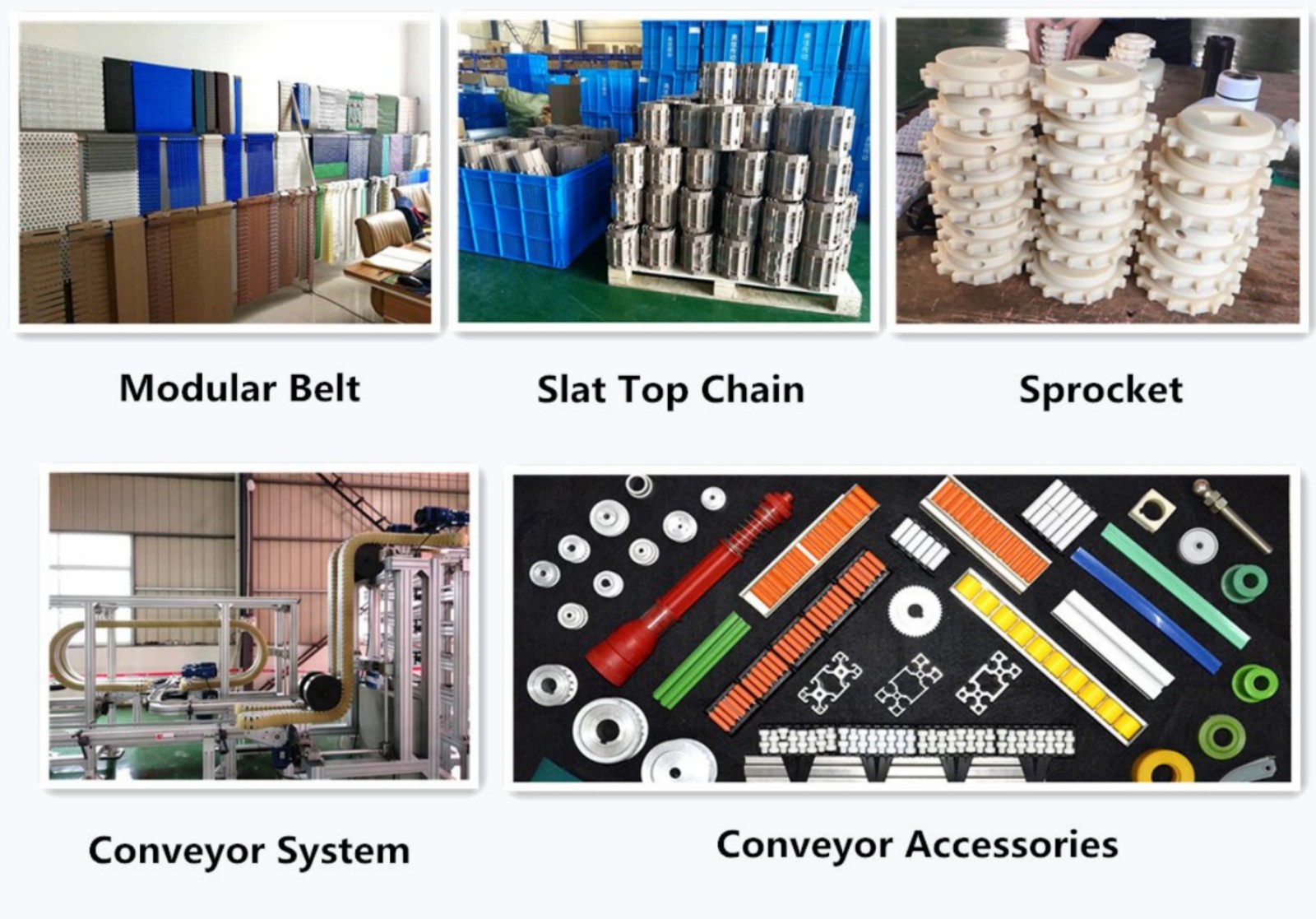

Why Choose Hairise Conveyor Sprockets

At Hairise Conveyor Systems, we provide high-quality plastic and stainless steel sprockets designed for modular belts, slat top chains, and other conveying components. Our sprockets are precision-engineered for long-lasting performance, smooth operation, and easy maintenance.

Whether you need conveyor sprockets for food processing, packaging, or industrial automation, Hairise has a reliable solution that fits your conveyor system perfectly.