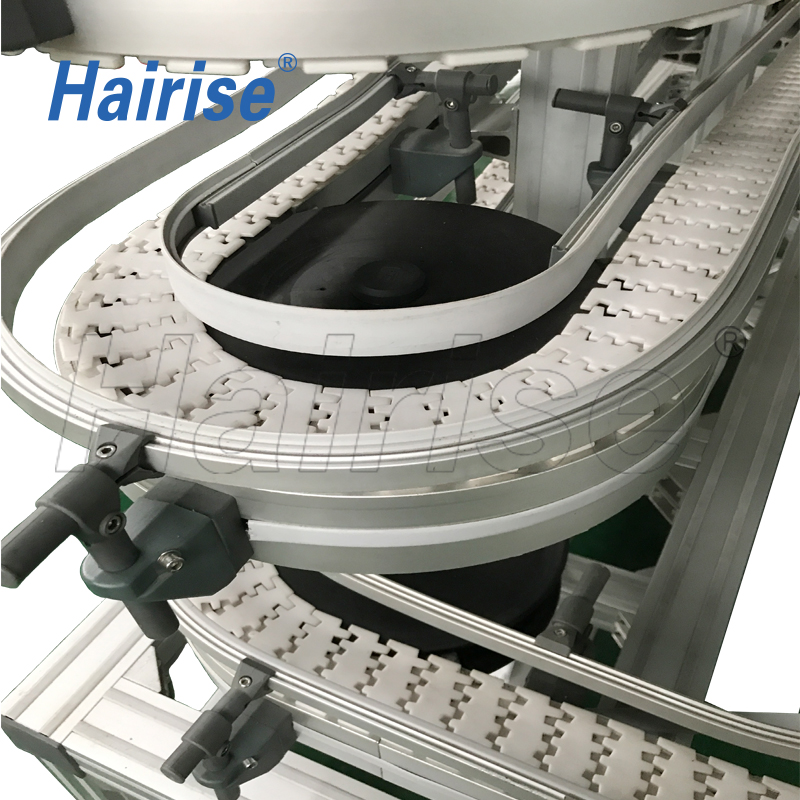

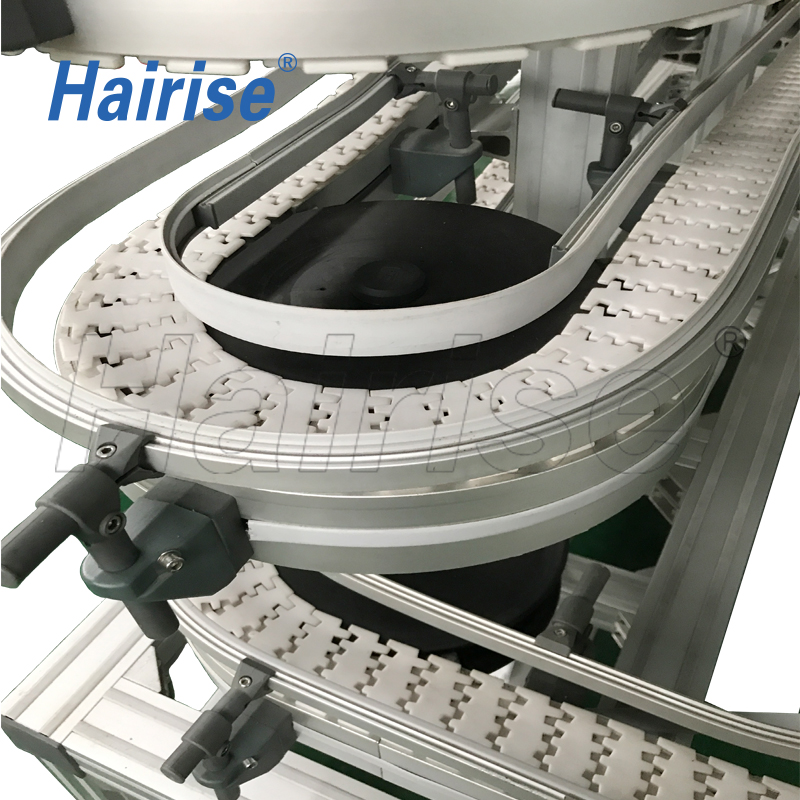

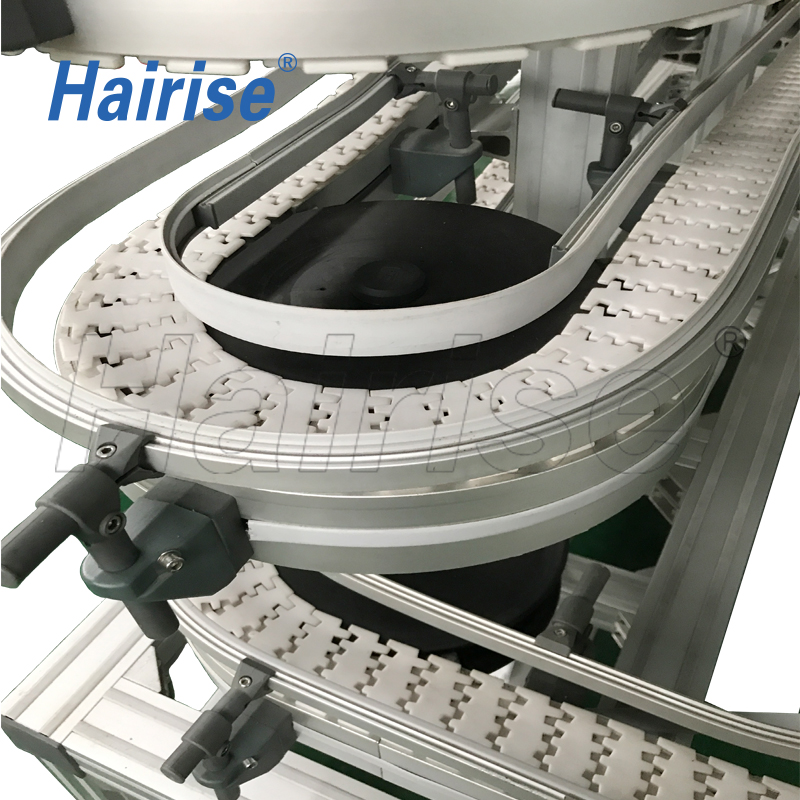

Spiral conveyors particularly suitable for a wide range of industries and applications, from food processing and packaging to logistics and manufacturing. The compact footprint of these conveyors means that they can be easily integrated into existing facilities without requiring extensive reconfiguration of the production layout. Moreover, the ability to customize the spiral curves and modules according to specific requirements ensures that each conveyor system can be tailored to meet the unique needs of different products and processes.

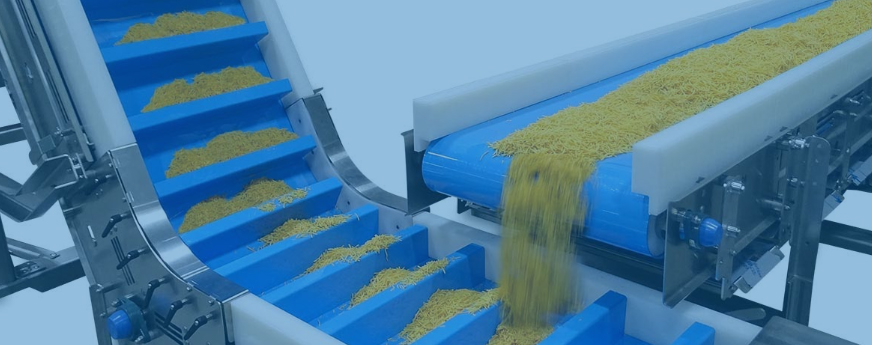

In addition to their space-saving benefits, spiral conveyors also offer significant operational advantages. The controlled speed and smooth movement of the conveyor belts minimize the risk of product damage, ensuring that items remain intact and undisturbed during transit. This is especially important for delicate or fragile products, such as baked goods, electronics, or glassware, which require gentle handling to maintain their quality and appearance.

Furthermore, the bi-directional drive system not only enhances flexibility but also improves the overall efficiency of the conveyor. It allows for seamless transitions between different production stages and can be easily adjusted to accommodate changes in workflow or production volume. This adaptability is crucial in modern manufacturing environments, where flexibility and responsiveness are key to maintaining competitive advantage.

The ergonomic design of spiral conveyors also contributes to a safer and more comfortable working environment for employees. By reducing the need for manual lifting and handling of products at different heights, these conveyors help to minimize the risk of workplace injuries and fatigue. This not only improves worker satisfaction and productivity but also reduces the potential costs associated with accidents and absenteeism.

Overall, spiral conveyors represent a highly effective and versatile solution for vertical transportation needs in various industrial settings. Their combination of space efficiency, adaptability, and ergonomic design makes them an attractive option for businesses looking to optimize their material handling processes while maintaining cost-effectiveness and operational excellence.